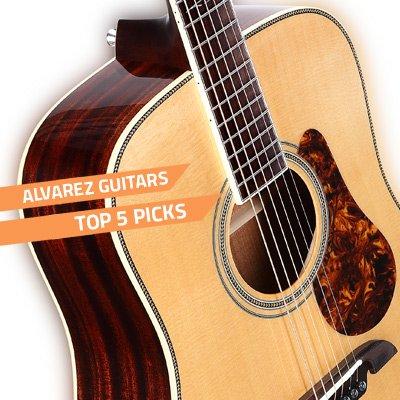

ALVAREZ GUITARS HAVE BEEN QUIETLY TAKING OVER THE MUSIC SCENE WITH THEIR WORLD CLASS GUITARS, ALL WITHOUT COSTING A FORTUNE – WE TAKE A LOOK AT WHAT SETS THEM APART FROM OTHER BRANDS.

The Alvarez guitars story is one of continuing success thanks to a few key elements including meticulous design processes, superior tonewood selection process and highly accurate tooling. But mainly, they just really care about their guitars and the connection the instrument has with the player. The quality and attention to detail shines through in each model, whether you choose the Artist, Cadiz, Jazz & Blues, Masterworks Series or Regent Series. Best of all, they’re extremely budget friendly proving that you don’t have to spend a fortune to get hold of a professional level guitar. So, we thought we’d take a look at what sets them apart. But first…

A BRIEF HISTORY OF ALVAREZ GUITARS

The story of Alvarez guitars starts with St. Louis Music/U.S. Band & Orchestra Supplies which to this day is still one of the largest general distributors of musical instruments and accessories in North America. Founded in 1922 by Bernard Kornblum, the company originally started out importing European violins to distribute across America, something which the brand is still very much involved in. Fast forward to the 1990s and SLM is now a major music distributor of musical instruments run by Bernard’s son, Gene Kornblum. However, the story of Alvarez guitars as we know it begins in 1965. Established by St. Louis Music in the late 60’s, the company began working with Master Luthier, Kazuo Yairi who was famed for producing handmade concert classical guitars that were renowned for their quality and playability. Gene and the Yairi factory began to design and develop a range of steel string guitars that would continue the hand-made high-quality feel that both entities appreciated. These guitars would take the brand name of SLM’s Spanish guitar line - “Alvarez”, eventually being sold all over the world. The collaboration would be a massive success and the Alvarez-Yairi guitars are still handmade in the Yairi factory today, in the small town of Kani, Japan.

Master Luthier, Kazuo Yairi[/caption] Over the next few decades the Alvarez and Alvarez-Yairi line of guitars became some of the leading acoustic guitar brands in the USA, introducing some unique design innovations into acoustic guitars along the way that would change the way we hear steel string guitars forever. As Gene Kornblum retired, the company was then sold in 2005 to LOUD Technologies Inc. Fast forward to 2011 after a short spell under the wing of LOUD and the Alvarez name was back safely in the hands of St. Louis Music who continue to develop the Alvarez range of guitars into what we know today. The Alvarez brand returned home and the team were hungry to improve on the legacy these guitars had made. This eventually resulted in the guitars becoming the weapon of choice for the likes of Joe Bonamassa, Bono, Johnny Cash, Crosby, Stills & Nash, Ani DiFranco, Jerry Garcia, Paul McCartney, Monte Montgomery, Carlos Santana, Bob Weir, and Thom Yorke.

SO WHAT MAKES ALVAREZ GUITARS SO DIFFERENT? HERE’S 10 REASONS!

Well, quite a few key elements make these guitars so revered, but the overall mission by the team at Alvarez was to make the best imported guitar the USA and the best value guitar in the industry. Here’s just a handful of reasons why we think they stand out from the crowd. Have a listen first...

1. HEAVY INVESTMENT INTO R&D

These are not your off the shelf guitars! The team at Alvarez guitars have spent a great deal of time developing several different bracing systems to suit the different styles of guitars rather than creating a one size fits all “cookie cutter” system. This is what makes the guitars sound so good – each series has its own unique bracing and construction process.

2. FST2 BRACING SYSTEM

The Forward Shifted Type 2 bracing system or FST2 for short is an innovative design feature that helps the guitar resonate louder and longer. This results in a huge sounding guitar that players really notice. You’ll feel the separation of the notes really come through and the articulation shine particularly in the Masterworks series.

3. ASYMMETRIC TONE BARS

The Alvarez guitar line also includes asymmetric tone bars to bring out the treble and bass notes within – all part of the reason you can hear each note accurately – go ahead and strum an Alvarez guitar, as you can really notice the difference.

4. SOLID MAHOGANY NECK BRACE

The team at Alvarez don’t cut corners, even when it comes to the parts you don’t see. Each Alvarez guitar includes a solid mahogany neck brace on the inside for structural integrity as well as resonance. Seriously – these guitars are really loud!

5. PINS ARE CLOSER TO THE RAISED SADDLE

You’ll notice that the pins on Alvarez guitars are closer to the string saddle and the angle of the strings is a little more severe. This means more tension, which means more sustain, which therefore results in more projection and a greater response to your playing.

6. AGGRESSIVE SANDING TECHNIQUES ARE BANNED

The finish of your guitar is the first thing you notice, so it needs care and attention in the production process. The skilled team at the Alvarez factory use a variety of different sanding processes during the 2-week paint job including manual hand sanding techniques after every coat to ensure there are no inter-coat scratches and blemishes. This results in a beautiful looking guitar with a premium finish you’d usually find on guitars at least double the price. Aggressive sanding techniques are banned! Each guitar is painted, sanded back then painted again multiple times to ensure clear coat.

7. ALL GUITARS ARE INSPECTED AND ADJUSTED BY THE ALVAREZ FACTORY BEFORE SHIPPING

Each Alvarez guitar goes through an extensive review process and are inspected for cosmetic flaws as well as inconsistencies in the nut, frets and playability within strict tolerance levels. Guitars are visually inspected by the QA team at Alvarez as well as electronically checked to ensure there are no faults in your guitar. This dedication to quality is one of the main reasons artists choose Alvarez. The guitar you get is ready to play.

8. ADVANCED TONAL RESPONSE

The unique Advanced Tonal Response process makes the wood of your guitar more stable and helps them to resonate better, respond faster to the subtleties of your playing and achieve better separation to each note. In addition, this makes the guitars far more stable in adverse weather/humidity conditions thanks to the 6-8 month wood drying process. Your guitar is “cooked” at 100 degrees for 48 hours in specially designed kilns to remove as much moisture as possible and any imperfections. Alvarez were early adopters of this process.

9. ALL TOPS HAND SELECTED

All the wood tops on your Alvarez guitars have been hand selected by luthiers at Alvarez. In fact, they pay extra to be the first team to choose the wood from the factory ensuring you get the best quality wood top for your guitar.

10. AFTER ALL THIS, THEY’RE STILL BUDGET FRIENDLY

After all the extensive research and development, hand made construction processes and quality control, the Alvarez guitar range still remains firmly in the affordable bracket. These guitars provide professional level playability and performance at a price that all guitarists can reach, proving you don’t have to spend a fortune to get a guitar that will last a lifetime and happily follow you in your musical journey for decades. This commitment to making superior quality guitars sines through in each aspect of Alvarez guitars. An Alvarez guitar works with you, not against you, to bring out the best in your playing. Don't believe us? Try one out at your nearest PMT Store today!